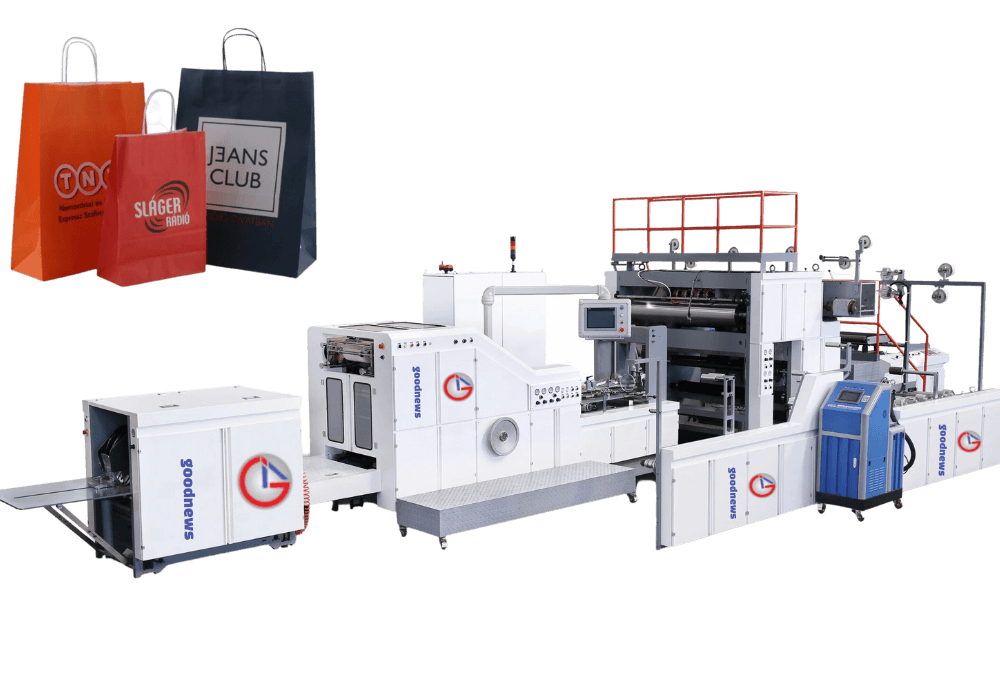

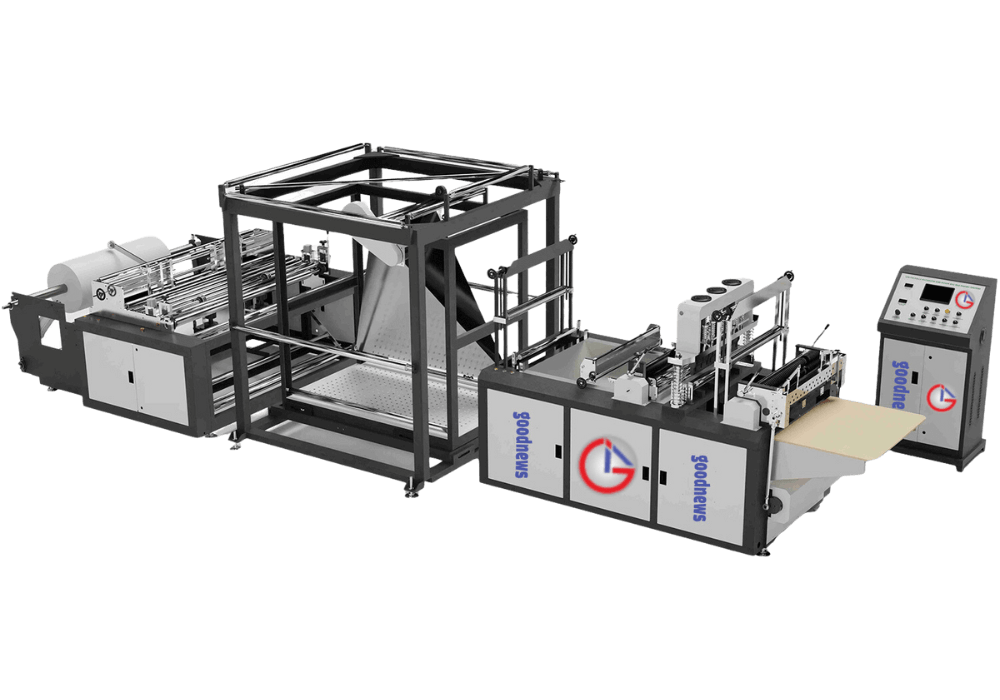

Square Bottom Paper Bag Making Machine

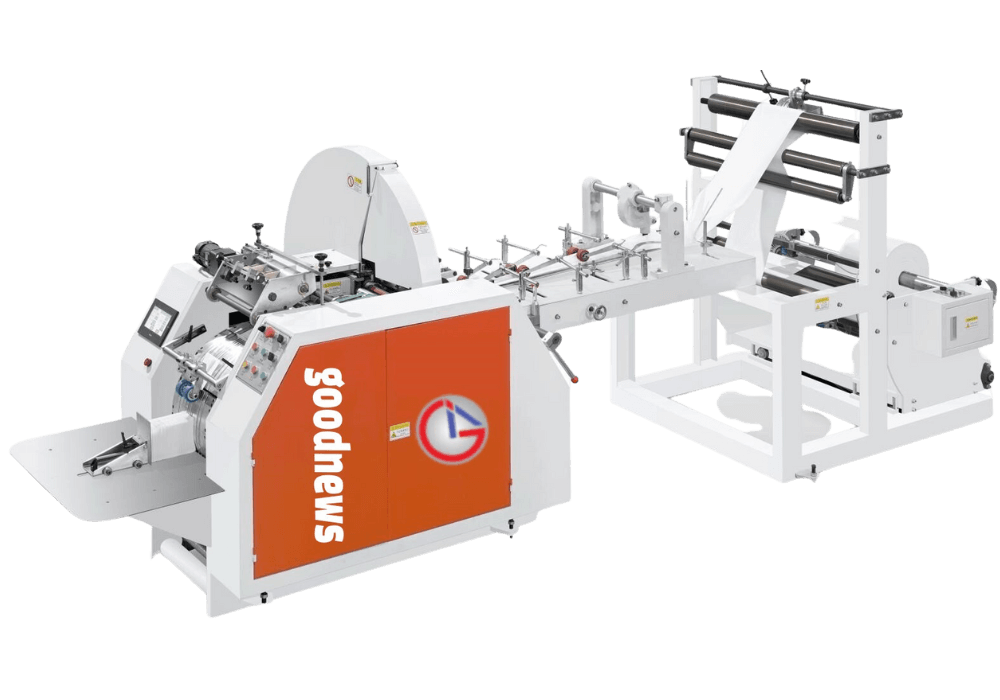

One such outstanding Square bottom paper bag making machine is available in the market which comes with various useful configurations which have been summarized below:

- Numerous wide bag size range

- High Performance

- Durability

- Easy Operations

- Automation that reduces overall wastage

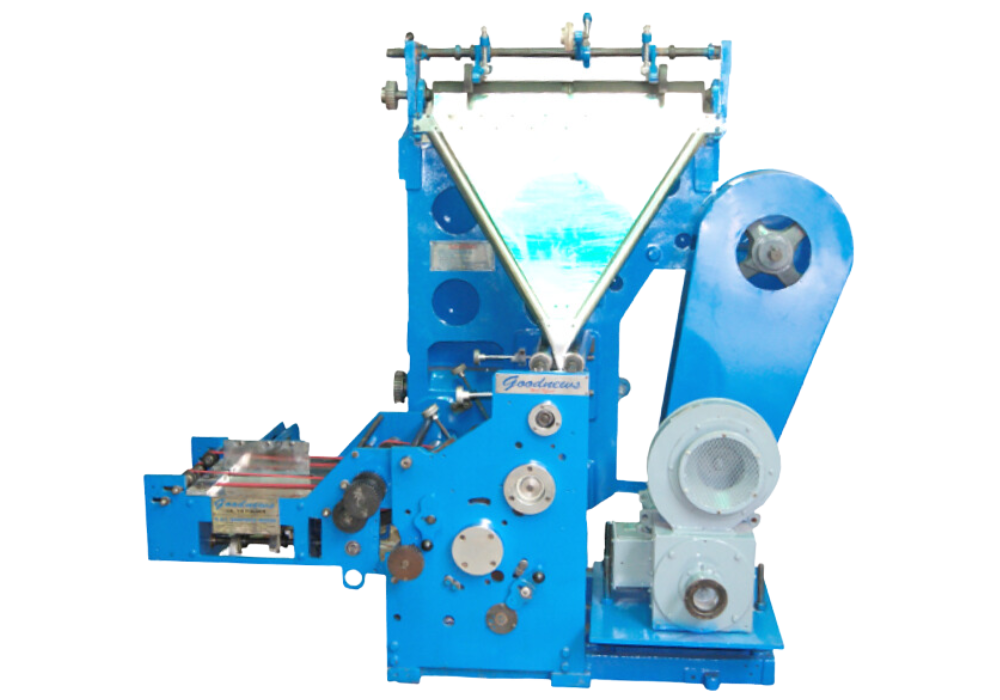

- Reel Feeding Unit

- Paper bag forming unit

- Machine Material

- Finished bag collection unit

- Machine Electrical panel

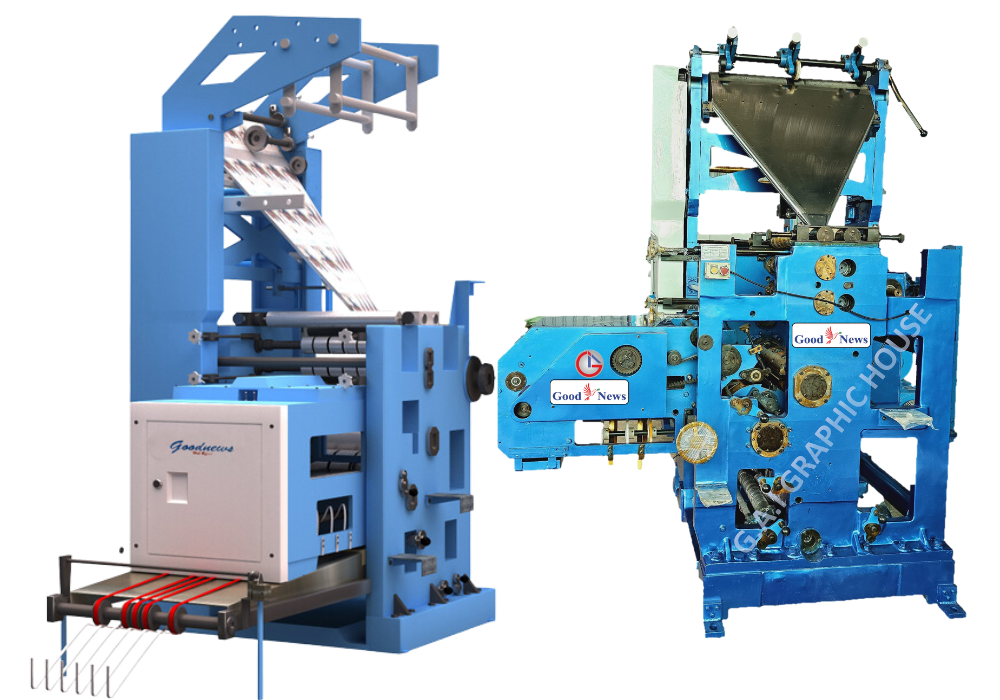

MACHINE PARTS

Technical Specification

| S NO | MODEL | GNSBM-360 | GNSBM-460 |

|---|---|---|---|

| 1. | Cutting Length | 270-530mm | 270-530mm |

| 2. | Paper Bag Width | 140-360mm | 230-450mm |

| 3. | Bottom Width | 80-180mm | 100-200mm |

| 4. | Paper Bag Thickness | 60-150g/m2 ² | 60-150g/m2 |

| 5. | Paper Bag Speed | 30-200pcs/min | 30-200pcs/min |

| 6. | Paper Roll Width | 480-1050mm | 690-1300mm |

| 7. | Paper Diameter | 1300mm | 1300mm |

| 8. | Inner Diameter of Paper | 76mm | 76mm |

| 9. | Power (3 Phase) | 15kw | 15kw |

| 10. | Weight (Approx.) | 8500kg | 10000kg |

| 11. | Dimensions (Approx.) | 10000*3700*2200mm | 10000*3800*2200mm |

Square Bottom Paper Bag Making Machine (GNSBM-360/GNSBM-460) G.A.I Graphic House is known to producing and manufacturing paper bag machines which are highly innovative and offers a great deal of advanced features which make them stand apart from the rest.

In 1870, Margaret Knight designed a machine to cut, fold and paste paper bag bottoms. This meant that she could produce flat/square-bottomed paper bags, a great improvement on the earlier envelope-style bag design.

Square bottom paper bag making machine has got lot of applications. It can be used to produce shopping bags, grocery bags, food bags, paper bags with handles and stylish bags used for gifts.

Quick Contact

If you have any questions or would like to book a session please contact us.